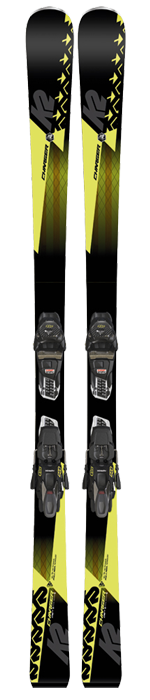

K2 Charger 2018/19

The "Charger" models from K2 are already in their third winter. They are fast and agile and show themselves confidently even in slightly powdery conditions. The Full Rox construction gives the ski models their basic sporty character, the Speed Rocker the ability to deal well with some snow. The right choice for all piste enthusiasts when it comes to having enough grip on hard slopes, being fast and maneuverable, but also gliding along confidently on soft slopes.

Speed Charger

Super Charger

Turbo Charger

Charger

Model comparison

| Model | Rocker | Core | Material, technology |

| Speed Charger | Speed Rocker | Aspen / Paulownia | Carbon grille, metal laminate, full length sidewalls |

| Super Charger | Speed Rocker | Aspen / Paulownia | Carbon grille, metal laminate, full length sidewalls |

| Turbo Charger | Speed Rocker | Aspen / Paulownia | Carbon grille, metal laminate, TwinTech sidewalls |

| Charger | Speed Rocker | Fir / Aspen | Carbon grid, triaxial braiding |

| Model | Medium width | Lengths | Waist | Radius |

| Speed Charger | 72 mm | 168, 175, 182 cm | 120-72-99 mm | 18 m (175 cm) |

| Super Charger | 76 mm | 161, 168, 175, 182 cm | 126-76-105 mm | 17 m (175 cm) |

| Turbo Charger | 72 mm | 158, 165, 172 cm | 129-72-107 mm | 13 m (165 cm) |

| Charger | 76 mm | 161, 168, 175 cm | 126-76-107 mm | 17 m (175 cm) |

K2 ski technologies

Full Rox - Construction

The "Full Rox" design is applied to the Charger models. This means the simultaneous use of the following technologies:

- Use of a solid wood core to maintain liveliness and energy of the ski

- Use of metal inserts to develop maximum force

- Use of sidewalls along the entire length of the ski to ensure maximum edge grip and

- Use of a carbon grid in front and behind the binding to improve damping and increase the torsional stiffness of the ski

Speed Rocker

K2 has 5 sophisticated rocker types. The Speed Rocker stands for maximum precision and turning ability on hard snow. The slightly raised and slightly longer shovel ensures effortless turn initiation and fast edge changes. The preload along the rest of the running surface guarantees racing precision and 100% edge grip.

Metal laminate

The ski has a lightweight titanium alloy that runs along the entire length of the ski above and below the core. Only the highest quality ski models from K2 are equipped with this most complex structure. Starting from the base, this construction consists of alternating layers of fiberglass and titanium wrapped around the wood core. Metal laminate provides superior damping, stability, torsional stiffness and precise and uncompromising performance for sporty all-mountain skiers.

Triaxial Braiding

Triaxial Braiding was developed by K2 in 1988 and is still considered the best process for joining fiberglass to a wood core. In this process, a pre-treated wood core is passed through a patented Triaxial Braiding machine, which wraps it with pre-braided fiberglass strands. This unique method produces skis with perfectly tuned torsional stiffness, and a forgiving character, without sacrificing the dynamics and lively flex of the wood core

Carbon grid structure

A new carbon grid structure inside the ski provides even more torsional stiffness and better edge grip.

TwinTech sidewalls

A durable sidewall construction typically used on TwinTip skis that makes the ski durable and protects the topsheet from damage.